Roof Screws: Ideal for Securing Metal Roofing

The roof screws are normally three-inch self-tapping fasteners, which are most commonly used to fasten metal roofing. Their uniqueness lies in their one-inch long protruding tail, which have been specially designed for roofing task and are sufficient enough to secure the first edges of metal roofing sections.

If in case, you are thinking of installing a metal roof over the top of an already constructed asphalt roof then you need to secure the first edges of each of the roof’s sections with 3-inch roofing fasteners.

These are mostly self-tapping lags, which are used to simplify the metal roofing task; which does not feature pre-drilled holes. Besides, these are quite faster and easier to secure, thereby lessening the risk of any injury, as it is the case with snapped ones.

These are basically used for sealing metal vaulting, as it does not feature any kind of support that would help seal the holes around the screws, as it is in the case of asphalt ceiling materials, which secure the holes around the vaulting nails. These particular fasteners are available in two types in the market. The first one features a sealer metal cap, which is fastened directly on the surface by the screw itself. The second one features either plastic or rubber washers, which are integrated into their bodies, which help secure holes automatically in the vaulting as they are tightened.

You can also go for vaulting screw gun alternatives. The metal ceiling cannot be installed manually, as the fasteners need to be installed within a gap of at least a gap of two feet. And by driving such a huge number of fasteners manually can be quite exhaustive, so it’s better to use screw guns. All you need is to switch over to new batteries at hourly gaps. These are usually rechargeable and so they do require charging on regular intervals. Around 4 batteries will be required for an 8 hour shift.

However, be warned that the roof screws, which are driven too deeply into the vault can damage the roof or can have their heads snapped off, thereby becoming quite impossible to remove.

.jpg)

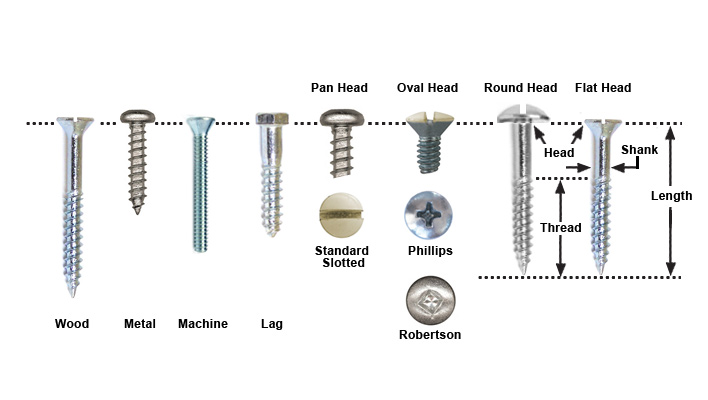

You can only settle down for a particular hardware item, which meets your requirement, provided you understand the basic difference between various screws, say

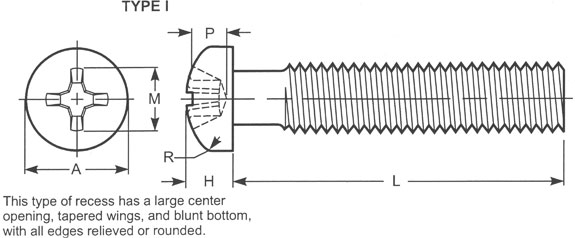

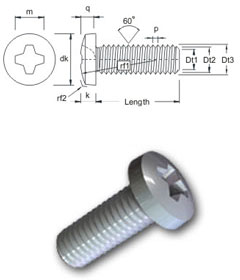

You can only settle down for a particular hardware item, which meets your requirement, provided you understand the basic difference between various screws, say  The barrel nut and its accompanying machine screw enables flush on both sides of the surface, which are tightened. Such kinds of bolts are much in demand, most probably because of their low profile as compared to other bolts.

The barrel nut and its accompanying machine screw enables flush on both sides of the surface, which are tightened. Such kinds of bolts are much in demand, most probably because of their low profile as compared to other bolts..jpg) These metal pieces were originally produced for the printing industry, so as to bind huge catalogs together. But now, with their multi-faceted features, they are also used in numerous other ways.

These metal pieces were originally produced for the printing industry, so as to bind huge catalogs together. But now, with their multi-faceted features, they are also used in numerous other ways.