Different Types of Screws and their Uses

Before elaborating the different types of screws available today in the market, let us first of all have a quick review on its definition.

So what is a screw?

A screw/bolt is a type of fastener distinguished by a circular ridge, known as threads which are wrapped around a cylinder.

While some screw threads are designed to get along with an internal thread, also known as complementary thread, there are some threads, which are fashioned to cut a helical groove in a softer material, say wood or plywood, when the fastener is inserted. The major function of a screw is to hold two objects together.

These kinds of fasteners are astonishingly versatile and powerful enough to be hold two different surfaces intact. The basic concept behind such metal objects functionality is their threaded cylindrical parts, which are designed to get inserted into any kind of material, be it a plastic, wood, metal or plywood. However, there are various types of screws available suitable for distinct surfaces.

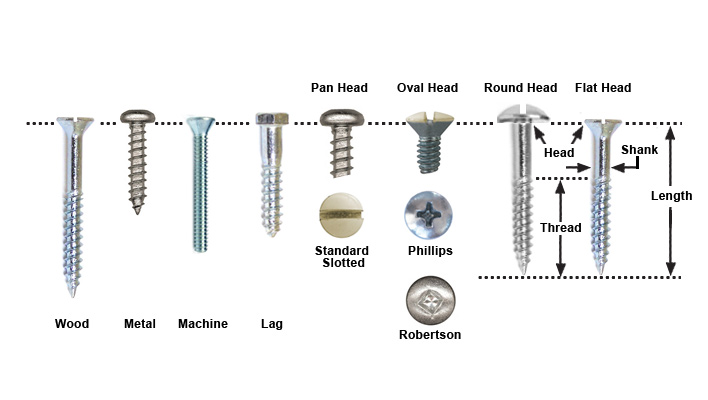

These types can be distinguished depending upon the driving methods, job requirement, head shape, type of threads and material used to make such metal pieces. Have a look!

Driving Methods

Slotted: The heads of such fasteners are most probably the most ancient and commonly used variety. The linear slot in the screw’s head is easily gets along-with any standard screw driver, such as the flat-head screwdriver.

Phillips: These are the enhanced forms of slotted ones. Their cross-shaped laps, which are not continuous up to the edge, will certainly require a Phillips-head screwdriver. The heads of such rivets, featuring a circular shape, enables a larger mating surface, thereby reducing the chances of wear and tear. Plus, they also prevent the chances of slipping. A cross head usually features 2 full-length slots, which can only work with a flat-head screwdriver.

Square: This type is also known as Robertson screw head and features a square dent to reduce the chances of slipping. It requires a special kind of driver for its usage.

Hex: This is again available in two designs. Such types of fasteners either feature a hexagonal recession in the head or do not have grooves at all. The hex socket screw/Allen screw requires an Allen wrench, featuring a hexagonal shaft and the other type of hex screw’s head is completely hexagonal in shape. A socket wrench is required to tighten or loosen it.

Apart from being available in above mentioned types, the screws are also available in various materials. While some are made up of steel and stainless steel, there are fasteners, which are made up of brass, nylon, aluminium and are also available with zinc and black-oxide coating.

Leave a Reply