A Brief Introduction to the Hilti Screws

Hilti screws are now-a-days, one of the most searched hardware items in the Internet. The Hilti Company is one of the leading fastener manufacturers in the world and their products are counted among the top-selling hardware supplies in the world market.

They have proved to be a great support for the international construction industry through their cutting-edge technology and high-end quality. Their products as well as their services enable the construction industry and even hardware industries with creative solutions and advanced benefits. Their head office is located at Schaan in the Principality of Liechtenstein.

They are active in more than 120 countries and their strength is up to 22,000, featuring skilled and proficient employees.

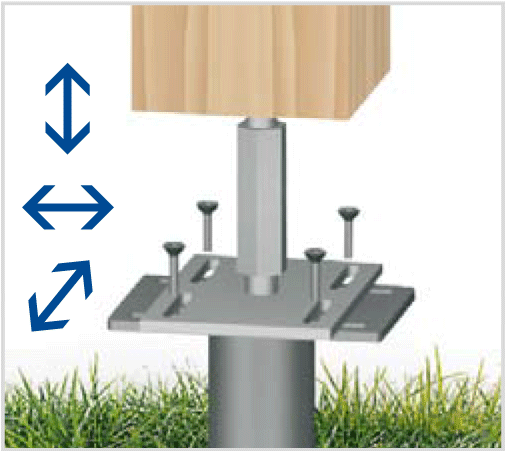

The Hilti Corporation or the Hilti Group manufactures and markets the fasteners and all sorts of related machines, such as the anchoring systems, drilling machine, screw fastening systems etc. The company’s products, which are already a hit among the construction world, these are even highly opted by the hardware and wooden manufacturing companies as well.

The company focuses mostly upon its anchoring systems, various kinds of screws and bolts, hammer drills, installation systems and fire stops, but their buck does not just stop here. Their extended best-selling products also include tools, such as laser levels, electric drills, power saws, heavy angle drills and much more in the list.

However, this company is more popular because of its Hilti screws, which are available in almost all ranges and sizes, suiting almost every field and industry.

Some of its best-selling fasteners are mentioned below. Continue reading!

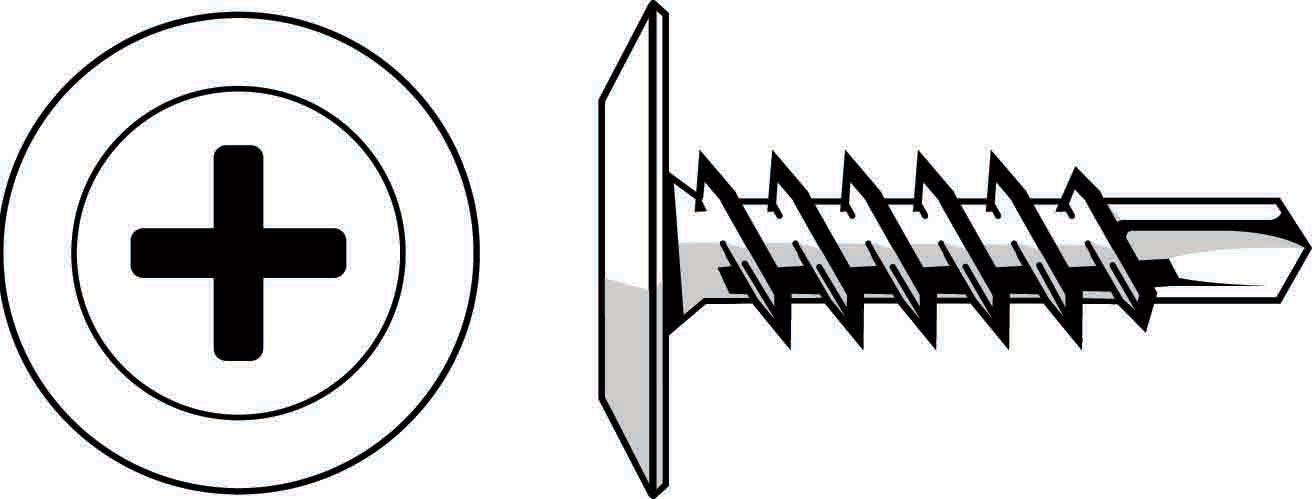

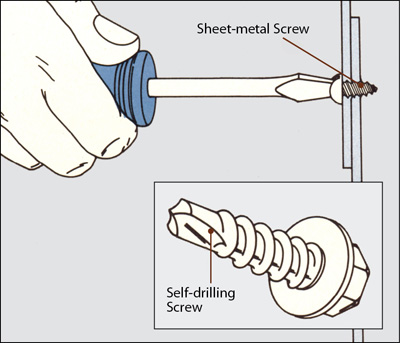

Sheet Metal Ductwork Screws

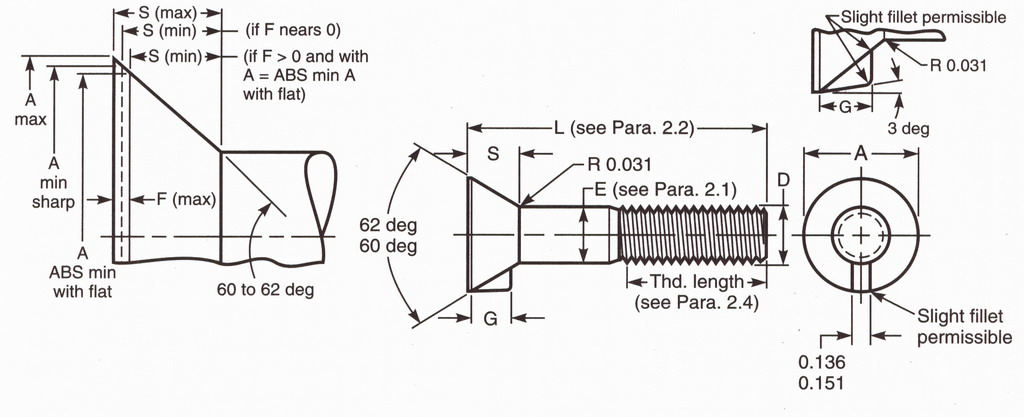

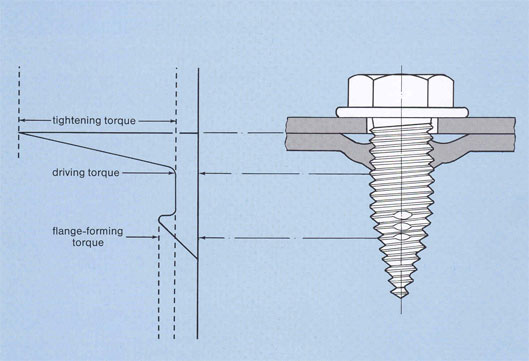

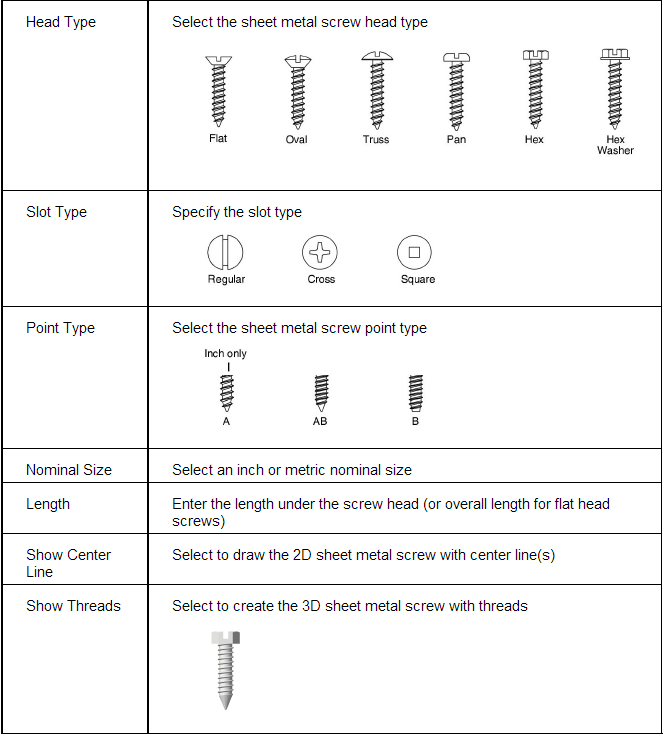

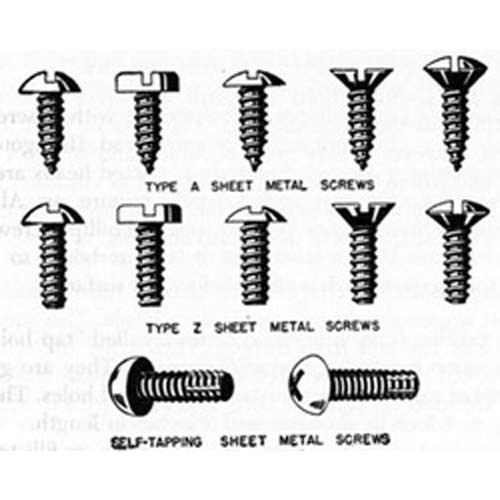

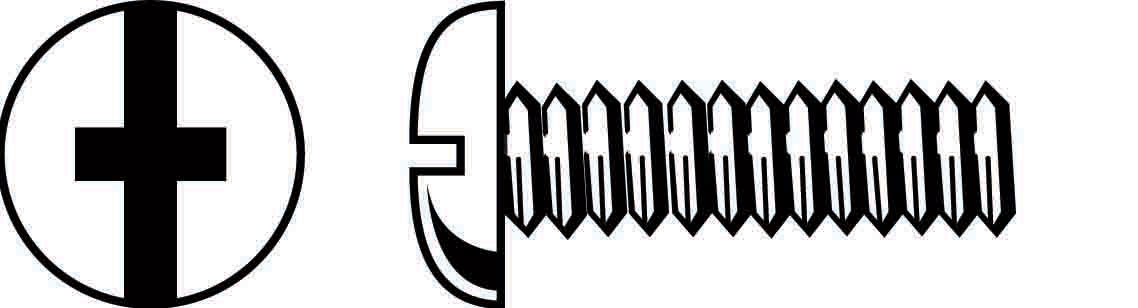

The S-MS HVAC zip screws are a combination of sharp as well as self-drilling screws. They are tailor made to attach sheet metal pieces, ranging from 18 to 28 gauges. They adopt the Hyper Thread technology to deliver the off-angle fastening capability, even in heavy-duty gauge sheet metal. These are also capable of being driven up to 30 degrees.

This advanced technology offers a tapered point and a shank for continuous driving with almost no metal filings. According to the Hilti Group, this specialized off-angle fastening quality in gauges ranging from 18 to 28 cuts off the installation time at much ease, while those enabled with high-profile heads and limited metal filings increase safety.

These specialized screws are made up of carbon steel along-with zinc electroplating and are available in two sizes. While the #10 S-MS is used for applications falling between 18 and 26 gauge and are driven with a 5/16-inch drive, the other type, the #8 S-MS is used for applications falling between 20 and 28 gauge and are driven with a 1/4-inch drive.

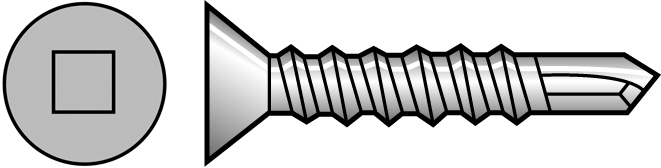

Sheet Metal Zip Screws

The S-MS HVAC zip screws also adopt the above mentioned technology to produce off-angle tightening, even in heavy-gauge sheet metal. This applied technology enables these screws with a tapered end and shank for consistent driving without metal filings.

They help join metal sheets up to two layers of 18-gauge and the heads of such fasteners help reduce any stress from base material supplanting. These are specially designed to fasten sheet metal ranging between 18 and 28 gauge, plus these are self-piercing and can be easily driven even at 30 degrees.

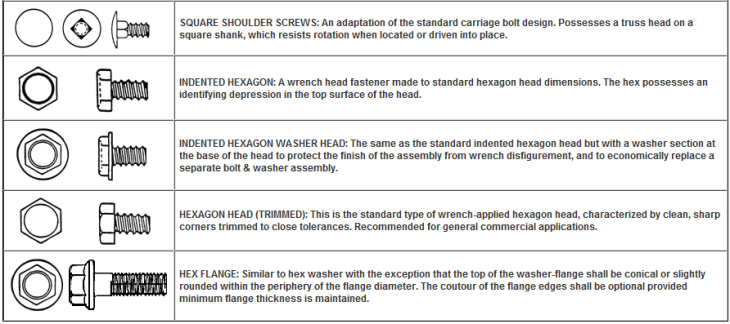

Now choosing the right type of fastener is necessary. You should select depending upon the type of your job. However, it can be bit complicated, as there is a huge variation, when it comes to materials, sizes, head styles, plated finishes and thread types. And if you’re thinking of going for a popular online store say Mutual Screw then twinfast screws are available in wide ranges. So you need to decide as per your basic requirements and then should go for a particular model. Buy

Now choosing the right type of fastener is necessary. You should select depending upon the type of your job. However, it can be bit complicated, as there is a huge variation, when it comes to materials, sizes, head styles, plated finishes and thread types. And if you’re thinking of going for a popular online store say Mutual Screw then twinfast screws are available in wide ranges. So you need to decide as per your basic requirements and then should go for a particular model. Buy

When you have got something to fix or any household task to do then you must be sure that you have got the appropriate tools. If your supply needs require an

When you have got something to fix or any household task to do then you must be sure that you have got the appropriate tools. If your supply needs require an

.png)