Gas Generators and Their Uses

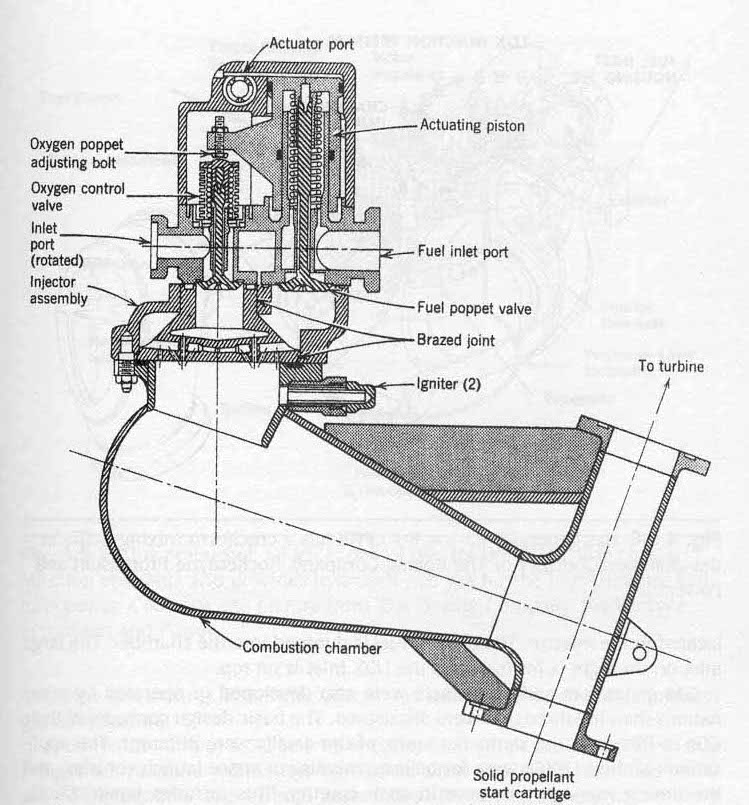

A gas generator is a kind of device which is quite similar to a solid rocket (it’s rocket with a motor that uses solid propellants) This kind of generator burns so as to produce huge quantity of relatively cool gas, without altering the temperature and specific impulse. The low temperature enables the gas to be used more easily in numerous applications, mostly to drive turbines.

This kind of dynamo is used in power turbopumps in rocket motors, so as to maneuver airbags and in cases where huge volumes of gas is required.

Gas generators are used in various settings and they’re readily available across the world. While local hardware stores stock small gas generators, the large sized dynamos are only available in select showrooms.

The best way to fetch for every kind of requirement is to go online, as one can get numerous options at one single store. Even such online stores are famed at offering customized gas generators, which are required for specialized job, such as in providing backup to a server farm in a blackout.

The term gas-generator cycle is often associated with such devices. This refers to a specific way of designing a turbopump-fed liquid rocket engine, where some of the gasoline is scorched to drive the turbo-pump, and then the excessive tucker is dumped through a spout instead of being induced into the main combustion chamber.

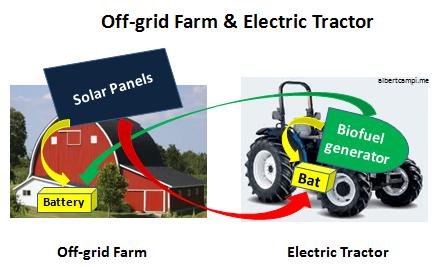

The fuel, which is utilized in the generator varies, as fuels such as gasoline, natural gas, propane, and other gases obtained from petroleum are used in this device. These are either produced in a biogas generator or created as an alternative fuel production. Biodiesel is one such example, which is used as a major fuel source for most of the standard generators.

This fuel is utilized to create mechanical energy, which is then converted into electrical energy. The amount of the energy produced depends upon the amount of fuel and components which are used. The size plays a relevant factor, as smaller the size of the dynamo, smaller is its capacity of production.

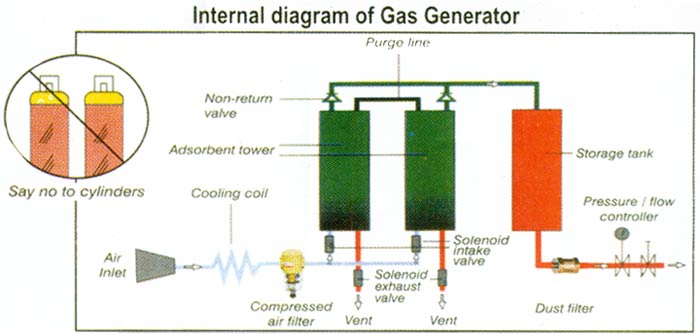

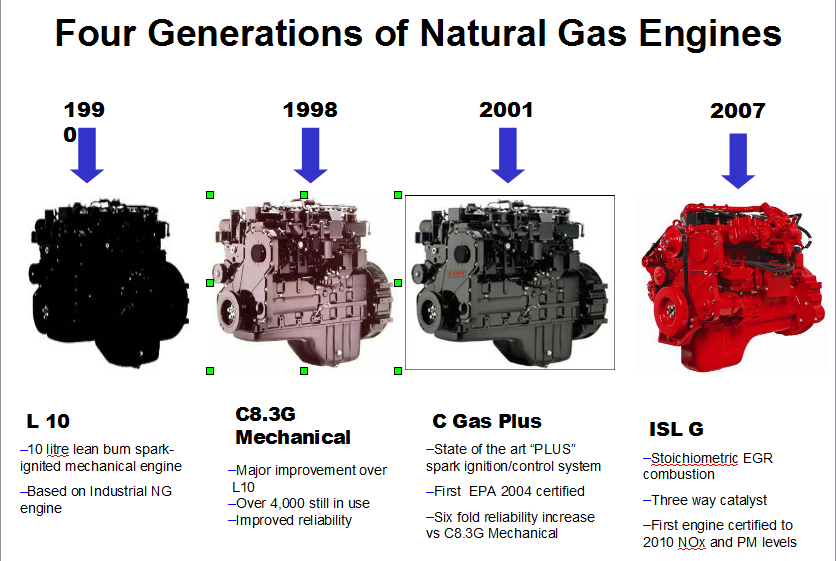

Schematic Diagram of gas generator

This device is more or less used as a backup power source. On a power failure, this device is used as a substitute for offering power supply to a definite community or structure.

Uses of gas generator

Utilities

Natural gas engine generators are used for electric utilities, so as to meet the basic electrical loads requirements. It is an ideal substitute in the absence of a reliable centralized power plant, as natural gas is readily available and is even cost-effective.

These devices are quite efficient in handling the peak loads. The peak time for grid electric power utility is in the early morning and in late afternoon, as everybody after work returns home and makes use of the electrical amenities. And when thousands of people collectively make use of the electricity, a huge power consumption occurs within a short time-period.

Benefits from utility gas generator include:

- Reduced energy costs

- Efficient use of resources

- Increased revenue opportunities

Commercial Facilities

Several commercial sectors such as resorts, shopping malls, administrative buildings, corporate, universities, data centers and medical institutions can effectively check on the cost by implementing Combined Heat and Power (CHP) with the help of pipeline natural gas.

Benefits include:

- Up to 90% of energy efficiency

- Reduced energy prices versus separate heat and electrical generation systems

- Reduced emissions versus separate systems

- Helps earn leadership in Energy and Environmental Design (LEED) Certification

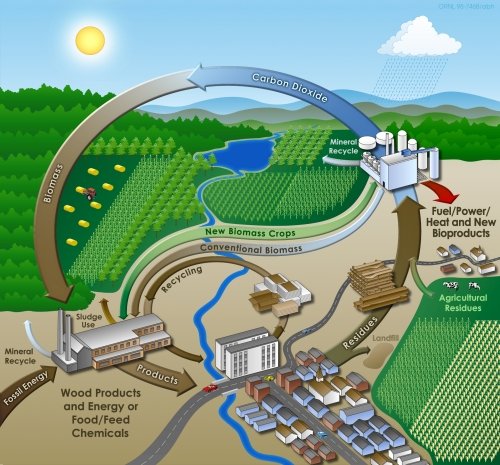

Agriculture and Bio-fuel Manufacturing

Biogas, which is a product of various agricultural processing and ethanol or bio-diesel manufacturing technique, is one of the major fuel sources for gas generators. There are specially designed dynamos to be run in this fuel.

Benefits include:

- Reduces carbon emissions through the liquidation of naturally-produced methane

- Enables valuable land space used for purifying organic wastewater

- Prevents odor and pest issues created by the decomposition of organic material

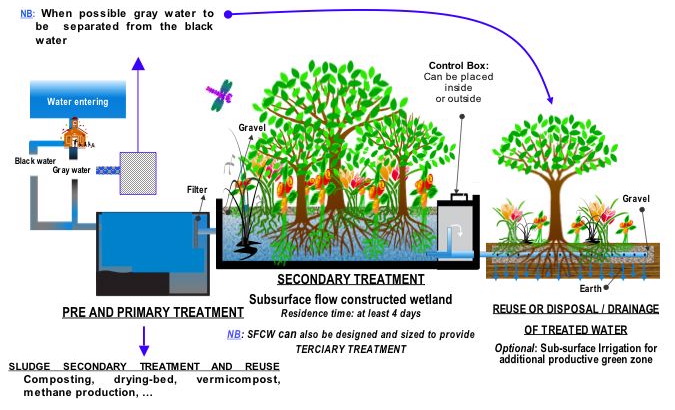

Wastewater Treatment Plants

Numerous wastewater treatments make effective use of waste sewage gas produced from facility processes as a major generator set fuel source. The gas is mainly composed of methane and carbon dioxide and is created from the wastewater digesters used in the water treatment process.

This gas is used to enable the treatment plant with electricity and heat for the digester.

Benefits include:

- Increases energy efficiency

- Reduces electricity costs

- Reduces environmental impact

Industrial Facilities

Numerous manufacturing plants, factories, refineries and regional heating plants reduce the cost on energy by implementing Combined Heat and Power (CHP) with the help of pipeline natural gas. These generators are famed to provide both electricity for electrical loads and heat energy for a facility’s thermal requirements.

Benefits include

- Offer up to 90% of energy efficiency

- Decre

With the availability of such kind of advanced amenities, it has become easy for us to manage our assets and essentials in a more organized way. Plus, their designs always render a fashionable look even to our overlooked closets. These days, with the increasing demand for such type of chambers, the market is today flooded with numerous companies dealing with various kinds of plastic storage canisters. These are usually light in weight and are also available in rugged pattern to manage fasteners in huge quantities.

With the availability of such kind of advanced amenities, it has become easy for us to manage our assets and essentials in a more organized way. Plus, their designs always render a fashionable look even to our overlooked closets. These days, with the increasing demand for such type of chambers, the market is today flooded with numerous companies dealing with various kinds of plastic storage canisters. These are usually light in weight and are also available in rugged pattern to manage fasteners in huge quantities.

.jpg)