Different Types of Tacoma Screws

The Tacoma screws are a leading brand in the fastener industry. They have been manufacturing different types of screws, bolts, nuts, studs, rivets and various other types of fasteners since 1946. Today, they offer their service to over 40,000 customers from their inventory of whopping 45,000 products.

Almost every product is sold under numerous categories, depending upon size and designs. Because of the abundance in varieties, their products easily satisfy customer requirement and thus, they play favorite among the supply chain industries such as Mutual Screw & Supply.

The tacoma screws are sold here in various categories. The different types of screws include the following:

Deck Screws

As the name suggests, these screws are used in wooden decks, which are made up of thin planks, which are quite prone to harsh environmental conditions. These types of Tacoma screws are specially designed to withstand the challenges, mostly faced by the lakeside houses.

Some of their major advantages include:

- They are corrosion resistant

- Their installation procedure is easy due to the sharpness of their point

- They can align smoothly against the deck surface, which is known as countersinking

- Ideal for composite decks, which are made up of pressure-treated wood. Their planks aren’t standard lumber and any regular screw may create ‘mushroom’ i.e. by using regular wood screws, the material can get pulled up in a hump around the screw head.

Dowel Screws

These are mostly cylindrical kind of metal screws, featuring two tapered ends and spiral threads. These are usually pointed on both ends, and thus can easily fasten two soft objects such as wood together.

Such fasteners are generally used with furniture, so as to create a conjunction with visible connectors. While one portion of the entire length is fastened into the joint, the other portion is driven all the way in when the connecting surfaces are aligned at the meeting point.

A 3D view of dowel screw

Drywall screws

As the name suggests, the drywall screws are used when drywall is installed on walls and ceilings. Drywall is a type of building material, which is made up of gypsum and other ingredients crushed between sheets of heavy paper.

These types of tacoma screws are mostly used to secure the drywall to the concerned surface, may be wood or metal framing. Moreover, their special design helps prevent dimpling on the surface. Unlike traditional nails, which leave behind holes/divots in the drywall, the drywall screws are threaded to grip both the framing member and the drywall firmly.

The primary feature of these fasteners, which offer the maximum advantage is their countersunk heads. The entire fastener is flushed within the sheet surface, thereby enabling a smooth finish. The countersunk head prevents the drywall screw from breaking the paper surface, which is a common problem with nails.

A lag screw is a huge, coarse threaded screw featuring a hexagonal shaped head, used for tightening or loosening of the screw. Unlike regular screws, which require a screwdriver, this kind of screw requires a wrench for its installation.

Its application is quite similar to bolts, as it is used in places where extreme clamping force and strength are mandated. Raising foundation of a home or securing a deck to the wall typically demands the use of a lag screw-mounting application.

Besides, the lag screws are also used in surgery in spiral fractures, swinging doors, mounting gates and garage door tracks.

While fastening a wooden plank or any other wooden piece, a pilot hole should be pre-drilled through the two boards first for easy installation of these Tacoma screws. The pilot hole enables the fastener to be effectively screwed without splitting either of the boards.

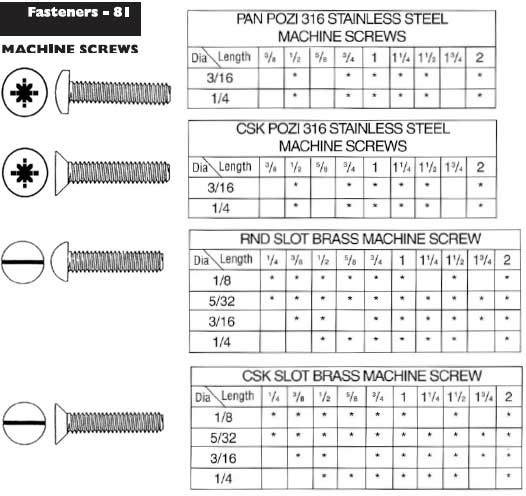

Machine Screws

A machine screw, which is also known as a machine bolt, is a typical screw specially designed to be attached to an pre-drilled, tapped hole on any metal surface, which is usually in alliance with a corresponding nut.

This kind of screw is usually smaller than the regular screws and range in size upto 3 quarters of one inch i.e. 19.05 mm. However, it is available in variations, depending upon shape of the head, slot type, length, overall size and material.

The two most commonly used screwdrivers used with machine screws are slotted and Phillips head screwdrivers. Other types of screw drives are also used, such as torx of star-shaped, 6-pointed and so on.

The machine screws are in varied types and are mostly differentiated by the characteristics of the thread.

Thumb Screws

Leave a Reply