Ground Screws: One of the Most Essential Fasteners in Fence Construction Work

The ground screws are one of the most essential fasteners in fence construction work. This particular fastener has also been a widely accepted practice for more than 10 years. However, the use of such screws especially in decks has not been as well accepted.

Such kinds of rivets have distinct advantages over conventional piles, posts or pad systems. These have considerably evolved in the past decade and are now available in a wider array of types and sizes.

You cannot blindly go for this particular screw; instead you should grab proper knowledge or seek advice from experts for making use of such rivets. As you know, today’s market is replete with several types of screws, which are designed to meet the specific needs and requirements, so selection of accurate fastener is also relevant. By this, you can always avoid the risks involved with implanting any kind of fastener, including screw, pile or post which is inadequate for your job.

You can come across numerous do-it-yourself decks online, but always go for such organizations, which are certified and already having a good rapport in the industry.

If your task involves one-level smaller decks, which requires you to go for a 4 by 4 post on a concrete deck pad; improper levelling can still occur, which can further lead to improper load distribution and shifting.

Besides applications including post & pad installations, you’ll also have to manage with pile & post installations as well. Piles are always a better option than pads in shelling out the weight smoothly below the deck into the soil, thereby rendering a groundwork, which is less likely to alter with various moisture content present in the soil and heavy deck cartage.

In case of multi-level mezzanines, you can go for pile systems, which are the common method to ensure endurance, durability and strength.

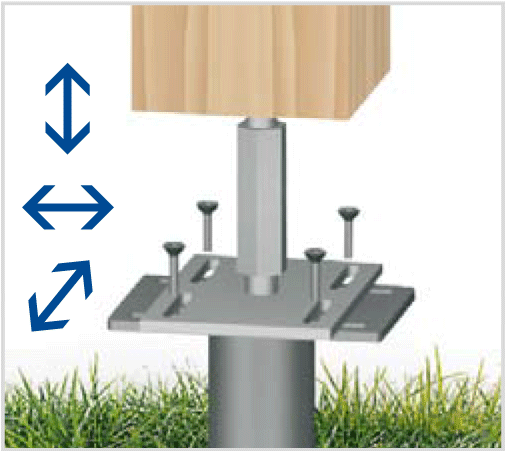

However, ground screws are always a better option, which are far more enhanced than pile-and-post construction, especially for the domestic projects. These fasteners can be easily removed and re-installed unlike piles, which usually involve digging and manual labour.

One of the most commonly used ground screws is the Krinner ground screws, which are ideal for faster, effective and long-lasting alternative to the concrete foundation.

Advantages of using ground screws

#Effective and flexible:

These fasteners are used as a groundwork for various jobs, including permanent as well as temporary ground augmented applications. This includes construction of single highway signs to large scale solar farms and fencing.

These specialized screws are ideal for both cohesive as well as granular soil types.

#Renders top precision and unsurpassed construction timing:

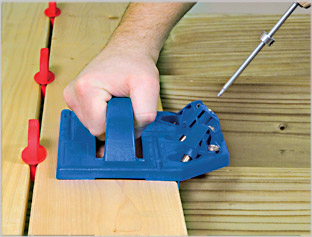

These fasteners are installed using a number of various aids and machinery. These are capable of getting inserted into the exact point in the ground within a sort span of time.

#Involves concrete-free job:

Their installation procedure does not involve excavation, digging or wet trades, thereby saving considerable amount of time.

#Cost-effective and long-lasting:

These are great alternatives to traditional construction work. These are made from 75-80% of recycled steel. Their installation procedure is vibration-free and endures low impact, thereby becoming easily removable. Plus, these fasteners put less effect on the landscape.

#Robust and simple:

The Krinner ground screws are rigidly tested and so have gained worldwide reputation and are ISO1461 certified.

#Ideal for highways:

In UK, most of the highway constructions involve these screws. In addition to, these have also been approved by the German Federal Road & Transport Authorities for the erection of all types of traffic signs.

#Consistent performance:

These fasteners render a 25-year guarantee, with an overall life span of up to 50 years.

This video explains how ground screws work for solar car ports. Do have a look!

When it comes to buying affordable and trendy screws online, I’m pretty sure you’ll be bombarded with an array of web stores selling the supplies. While some sites would assure you to enable with the sturdiest types, others would try convincing you with their discounts and special offers.

When it comes to buying affordable and trendy screws online, I’m pretty sure you’ll be bombarded with an array of web stores selling the supplies. While some sites would assure you to enable with the sturdiest types, others would try convincing you with their discounts and special offers.