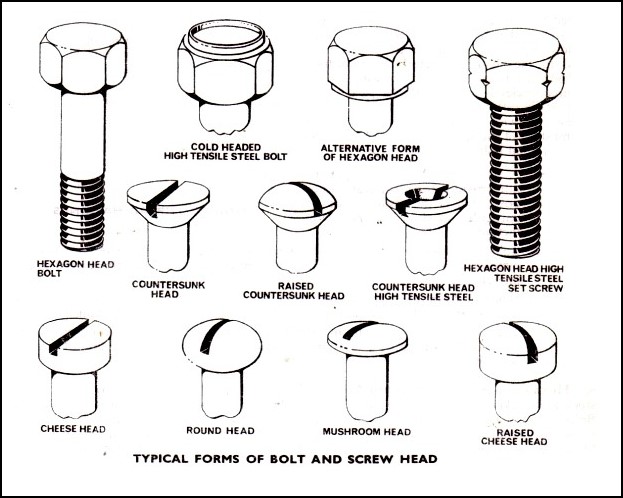

Different Types of Bolts

Different types of bolts are available online, so as to fit into various industry requirements. Following are the most commonly used types of bolts, used in various applications and sectors. Do have a look!

#Anchor Bolts

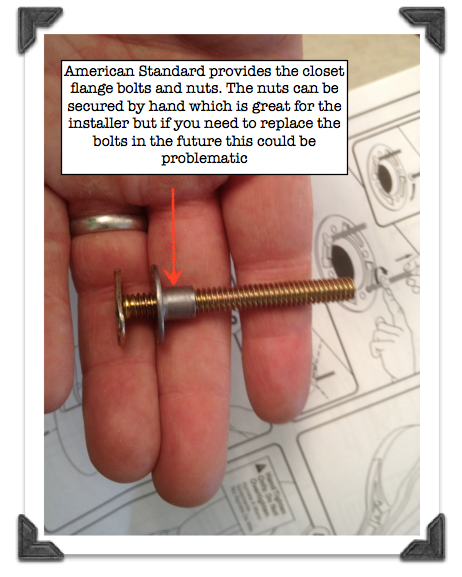

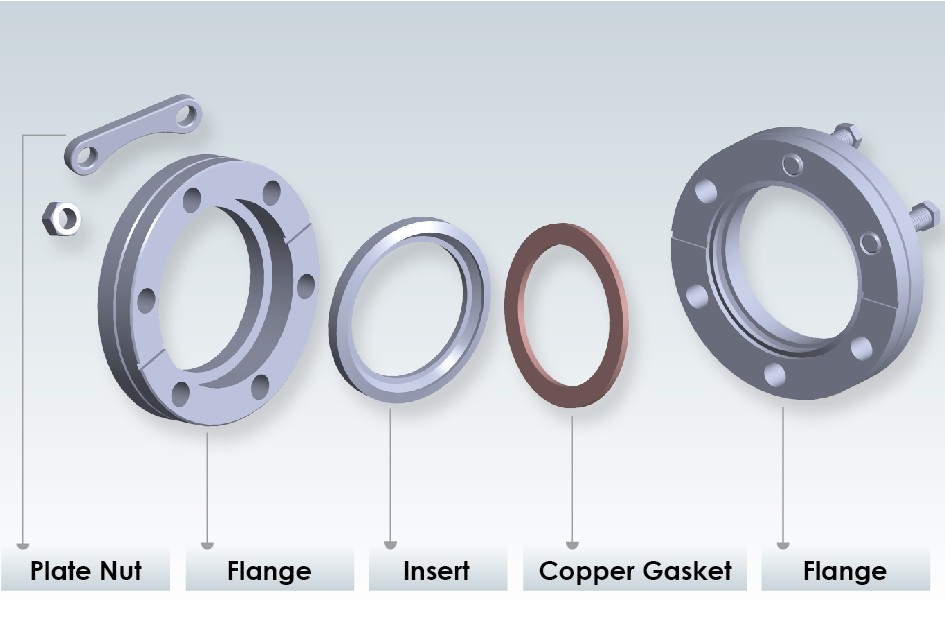

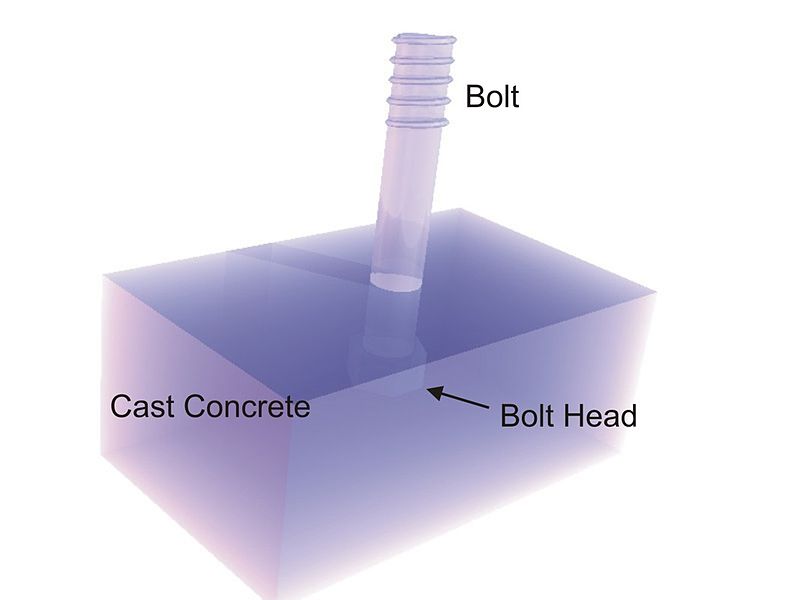

Anchor bolts are used to fasten various kinds of objects or structures to concrete. These bolts are available in various designs, which suitably fit into almost every industry requirement. These types of rivets are enabled with a threaded end, to which a nut and washer are fastened for the external load.

These fasteners are extensively used in all sorts of fields, ranging from nuclear power plants and standard buildings to dams and home renovations. They help in firmly fixing implanted plates to a concrete foundation, featuring a structural steel element.

One of the simplest forms is the cast-in-place anchor, which is the strongest type of fastener. It features a standard bolt with a hexagonal head, which is fixed in a wet concrete before it sets. It is used in heavy-duty machines mounted on poured concrete floors.

Features

- Rust-resistance

- Sturdiness

- High consistency

Other commonly used designs features a bent bolt along-with a hook at the end. Click here to know more about these bolts.

#Roof Bolts

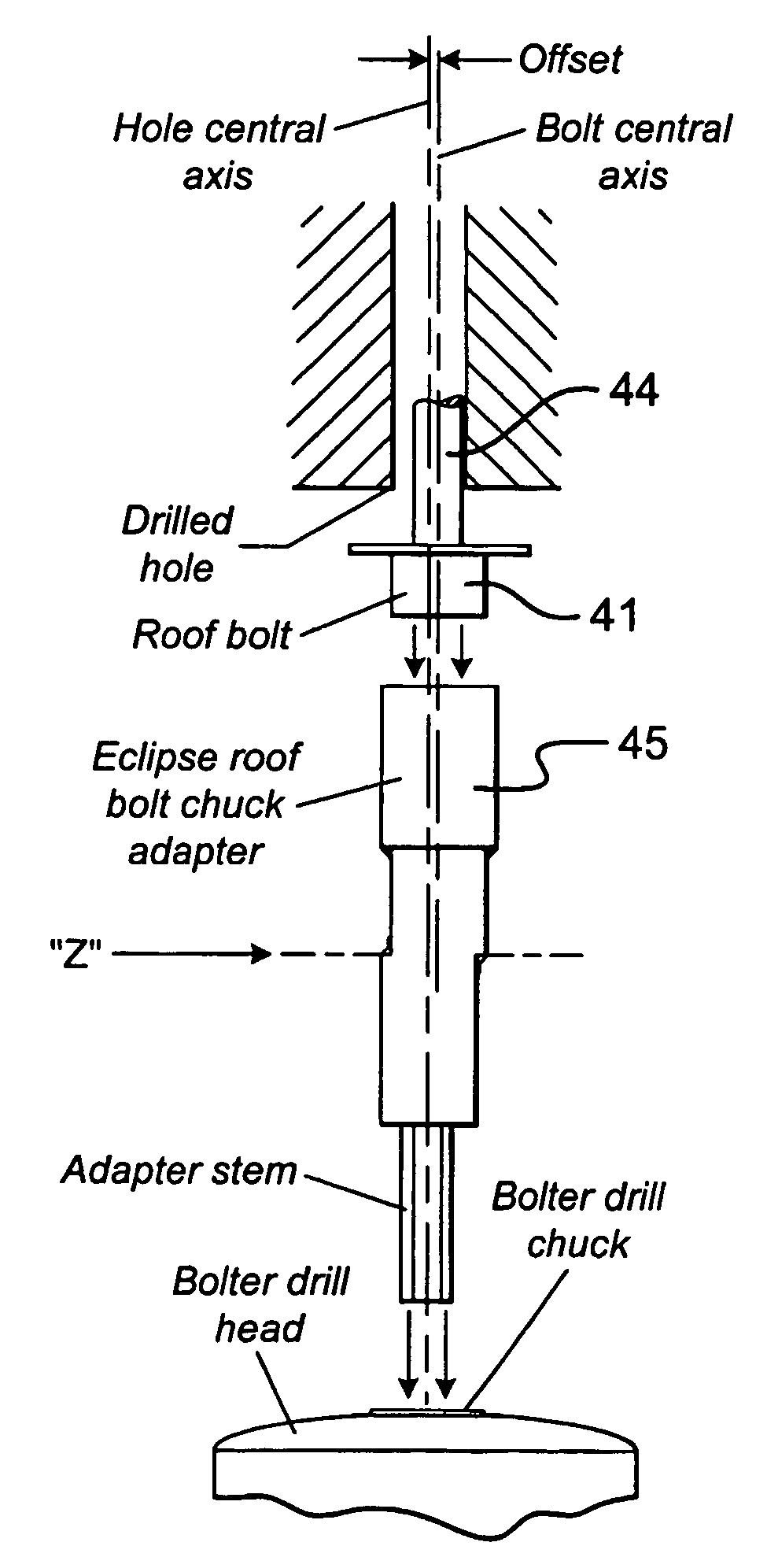

A roof bolt usually comprises of a shaft for injection into a pre-drilled hole, mostly in a mine roof.

The head of such bolts is counter-balanced with respect to the longitudinal axis of the shaft so that when the rivet is rotated by means of its head, the shaft creates a circle of greater diameter an offset between 0.08″ and 0.25″. Usually, the counterbalance should be between 0.10 and 0.16 inches.

This kind of method is implemented, so that at least 90% of the bolts produced so far have their head central axis equipoised with the longitudinal axis of the shaft by 0.08″.

A typical mechanical roofing bolt incorporates a 3-leaf mechanical expansion shell.

While installing, the expansion shell gets activated by employing torque over the nut end, thereby forcing the shell to expand and get engaged in the hole.

.png)

Benefits

- Enables a versatile system for rock reinforcements

- Renders immediate support for installing 300 mm from the face

- Easy installation and production time saving

- Cost effective support method

- Less prone to blast damage on the face

- Easily gets along-with mechanical equipment

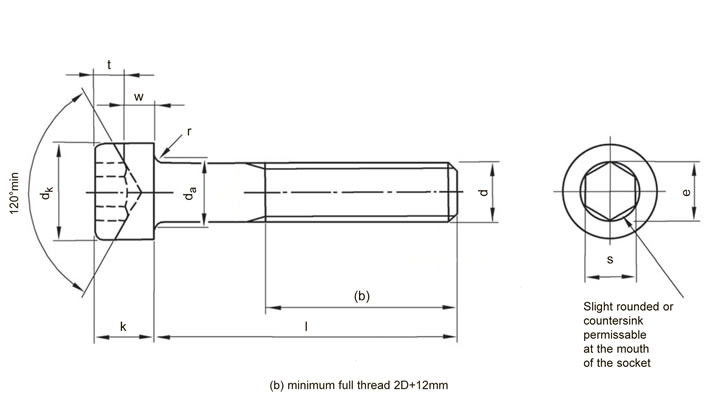

#Hex Socket Bolts

These are six-sided bolts, specially designed to meet various industry standards. The hex socket feature is shown in all SAE hex bolts, ASTM A307 grade A bolts. There are heavy hex socket bolts available in the market, which are required for A307 grade B, A325 and A490, requiring a hex pattern.

These are used in various applications, including wood, steel and construction supplies required for bridges, docks, buildings and highway structures. These rivets are also known as headed anchor bolts.

Features

- Standard: DIN912

- Size: M6-M64

- Material: carbon steel,stainless steel

- Surface treatment: self color, zinc plated, H.D.G

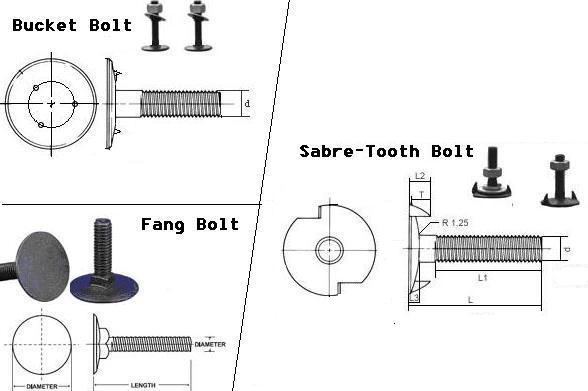

#Elevator Bolts

These bolts were introduced in mid-18th century. In those days, these were used to fasten the lift buckets with a belt, so that the grains could be lifted to be stored in the vertical grain cabinets of the lift. Today, these rivets are rather used in broad applications, which are altered to transporter systems.

Features

- Material: General Carbon Steel, Carbon Steel with zinc plated, Stainless Steel

- Intensity of Bolt : Class 4-8

- Model: Standard Bolt, Flat Countersunk Bolt, Fang Bolt (Tooth Bolt), Belt Bolt.

- Standard: GB, ISO, ANSI, DIN, BSW, JIS

- Dimension: M3-M22

- Length: 10 mm-600 mm

- Grade: 4.8, 6.8, 8.8, 10.9, 12.9

Visit here to know more about these bolts.

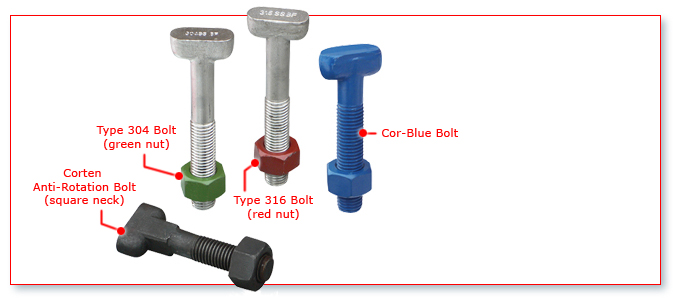

#T-Bolts

T-bolts enable a durable and convenient connection. These fasteners swivel into the required position, so that they can be easily fixed soon after a structure is assembled. These are used in building, instruments, automobiles, furniture etc. These rivets are available in aluminum, brass, carbon steel, stainless steel and copper. These are also available in zinc plate, black, chrome plate, HDG etc.

Features

- These can be installed anywhere along the profiles T-slot and rotates into position

- Their grooves bite into proile to lock the T-bolt into position, offering ESD

- protection and resistance to vibration

- Huge contact surface improves gripping of the str