All You Wanted to Know About Finish Nuts

Finish nuts are usually hexagonal nuts, having six sides, as this kind of shape is the easiest to grasp. These nuts are small threaded metallic blocks and mainly help in securing bolts. These nuts along-with bolts fasten machine parts for assembly in step by step fashion.

These are also known as “hex nuts” because of their hexagonal-shaped heads.

Specifications

The hex finished nuts are available in ASTM A563-A grade and are compatible with low carbon steel bolts, including SAE grade 2, ASTM A307, ASTM F1554 grade 36 and AASHTO M183. Besides, these rivets are also available in SAE grade 5 and grade 8 nuts in a finished pattern.

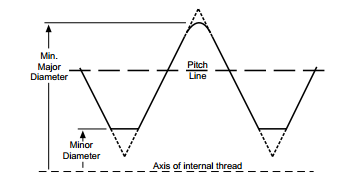

The sides of these nuts help in easily attaching to pliers and wrenches, so as to grip the nut and apply the required torque to it. Some of these metal pieces are hot-dip galvanized and thus add 2.2 to 5 mils of thickness to the threaded portion of a fastener.

The galvanized finished nuts are tapped flabby to adjust with the corrosion-resistant coating characteristic on the bolts.

History

The Besson factory was the first to manufacture these nuts in 1568. In those days, these nuts were mostly used to festoon sleighs and carriages. Later in 1770, handmade wing nuts were created in North America for the same purpose.

In the year 1818, Micah Rugg of Southington Township, Connecticut, designed the first nut and bolt manufacturing machine in North America, thereby paving the path for broader production of these fasteners.

Popularity

Although the nuts and bolts industry witnessed better advancements, but the use of these finish nuts are still in extensive use. No other nut can beats its usability and sheer versatility.

Materials

The hex finish nuts are usually made from steel, which has been specially designed with the help of a steel cutting machine. The entire manufacturing process is relatively fast, and thousands of nuts can be produced within a matter of minutes.

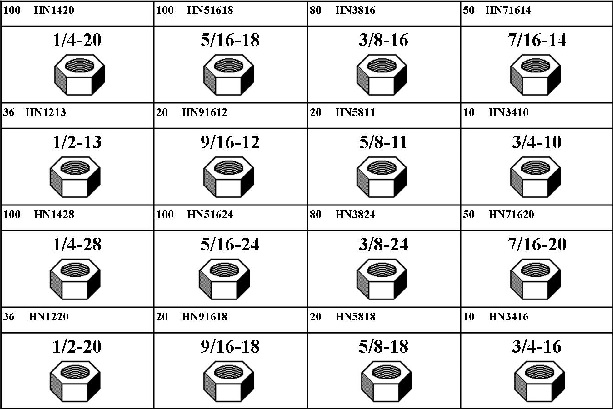

These days, nuts are available in steel, stainless steel, grade 5 black oxide, aluminum alloy, grade 2 zinc plated, grade 5 zinc yellow, brass, nylon patch, L9 Cad yellow, metric hex, silicon bronze, MS51971 Hex Nuts (Coarse Thread), MS51971 Hex Nuts (Coarse Thread) etc.

However, steel hexagonal nuts are used more than any other frequently used type.

The hex finished nuts are generally coated with a rust-proof material, so to prevent it from rusting. Nuts, which are rust-proofed, can be used for both indoor and outdoor purposes.

Types

#Grade 2

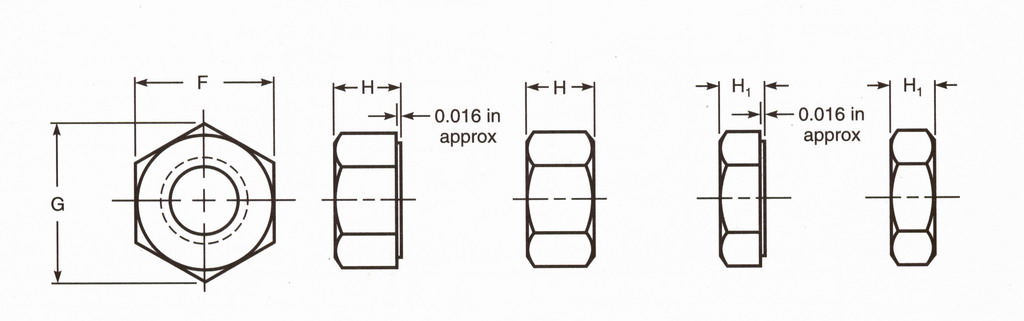

The Grade 2 type finish nut is a hexagonal shaped threaded fastener, with thickness of 0.875 D, where D is the normal nut size and a width of 1.5 D across the flats. These rivets are usually made up of low carbon steel. This is the most versatile and widely used design in the nut industry and can be used with any low carbon bolt, which is not heat-treated. The bolts should have a minimum tensile strength of 74,000 psi or less.

Their composition includes the following:

- Carbon: 0.47%

- Phosphorus: 0.12%

- Sulphur: 0.23%

- Coarse thread: 90,000 psi

- Fine thread: 80,000 psi

#Steel Hot-Dip Galvanized

This kind of finished nut is also a 6-sided internally threaded fastener, with a thickness of 0.875 D, where D is the normal nut size and a width of 1.5 D across the flats. These are also made from low-carbon steel, featuring a galvanic zinc coating.

These are used with low carbon bolts and screws, by applying a minimum tensile strength of 74,000 psi or less, so as prevent the fastener from moisture, salt and other such corrosive conditions.

Their composition includes the following:

- Carbon: 0.47%

- Phosphorus: 0.12%

- Sulphur: 0.23%

- Rockwell B68 – C32

- Coarse thread: 68,000 psi

- Fine thread: 60,000 psi

#Stainless Steel, 18-8 & 316

Such types of six-sided threaded fastener are hexagonal in shape, with thickness of 0.875 D, where D is the normal nut size and a width of 1.5 D across the flats and are made from austenitic alloys.

These rivets are used with stainless steel bolts and screws, by using a specified minimum tensile strength, which is either equal to or less than the specified stress of the mating nut.

Both types of stainless nuts are corrosion resistant, as they are made up of 316 stainless steel. Thus, they have greater resistance power as well as superior strength at raised temperatures.

The composition of 18-8 stainless steel finish nuts include the following:

- Austenitic alloys of 303, 303Se, 304, XM7

- Chromium: 18%

- Nickel: 8-10%

- Rockwell B95 – C32

.jpg)

.jpg)