Blind Rivets: Replacing the Traditional Clinch Bolts

A rivet is usually a kind of solid mechanical permanent fastener. It comprises of a smooth barrel-shaped rod with a head at one end and the opposite end is known as ‘buck-tail’. It is available in various types, designed specially to meet various industry requirements and accessibility. These include solid round head, structural steel type, semi-tubular, blind rivets, drive, flush and friction-lock type to name a few.

During installation, the affix is inserted into an already drilled or punched hole and its tail is bucked or deformed, so that it stretches up to 1.5 times than the original shaft diameter, thereby helping the rivet be in place. You can distinguish the two ends of the fastener by yourself. While the original head is known as the factory head, the deformed part is known as the buck-tail or shop head.

The head, located on the each end of an installed bolt, efficiently supports tension loads, which are parallel to the axis of the shaft. However, it is more capable of holding shear loads, which are vertical to the axis of the shaft. Fasteners like rivets and bolts are best suited for tension applications.

Even fasteners used in traditional wooden boat building, which is one of the oldest fields of engineering, such as clinch bolts and copper nails also work on the same principle as the rivets do. However, the rivets always have advanced features and better usability and so are now highly in demand.

The blind rivets, which are also known as pop rivets, are tubular in shape and are enabled with an arbor (mandrel) at the center. The assembly of this metal piece is inserted into a pre-drilled hole by a specially designed device, which is capable of drawing the arbor into the rivet.

Such kinds of fasteners feature non-locking arbors and are not ideal for fixing critical structure joints, as they may fall out due to the external vibration. In this way, a hollow rivet will be left out, featuring a less low load carrying capacity.

In addition to, they even become more prone to get spoiled because of the corrosion. The blind rivets, unlike other patterns can be easily inserted into a joint from only one side of the structure and is rather ‘blind’ at the other end.

The barrel nut and its accompanying machine screw enables flush on both sides of the surface, which are tightened. Such kinds of bolts are much in demand, most probably because of their low profile as compared to other bolts.

The barrel nut and its accompanying machine screw enables flush on both sides of the surface, which are tightened. Such kinds of bolts are much in demand, most probably because of their low profile as compared to other bolts..jpg) These metal pieces were originally produced for the printing industry, so as to bind huge catalogs together. But now, with their multi-faceted features, they are also used in numerous other ways.

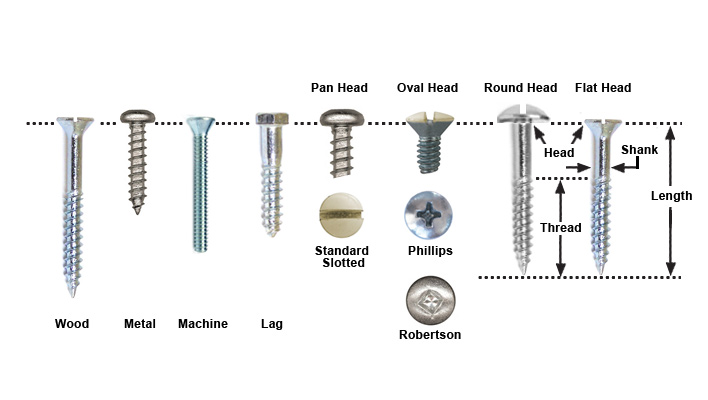

These metal pieces were originally produced for the printing industry, so as to bind huge catalogs together. But now, with their multi-faceted features, they are also used in numerous other ways. You can only settle down for a particular hardware item, which meets your requirement, provided you understand the basic difference between various screws, say

You can only settle down for a particular hardware item, which meets your requirement, provided you understand the basic difference between various screws, say

.jpg)

.jpg)