Multiple Uses of Flange Bolts

The company, Mutual Screw and Supply has gone a long way in establishing a brand of excellence and the best available artisanship in the industry since its establishment in 1947. Presently the company is selling its products all over US and parts of Canada & even overseas.

Today this company has become a well-known hardware supplier in the world of online marketing. We, at Mutual Screw are specialized in the manufacturing of flange bolts and various other kinds of fasteners, including all types of screws, hardware kit and much more.

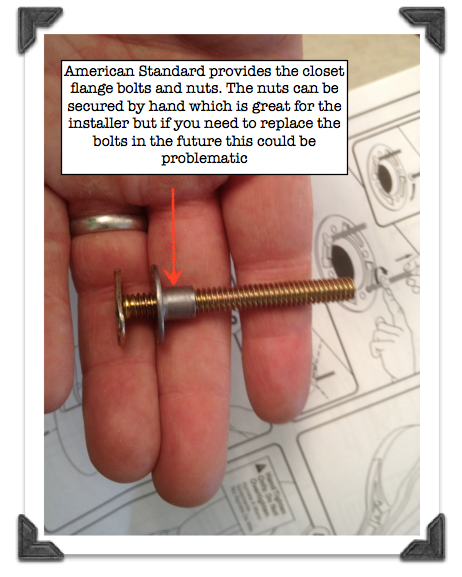

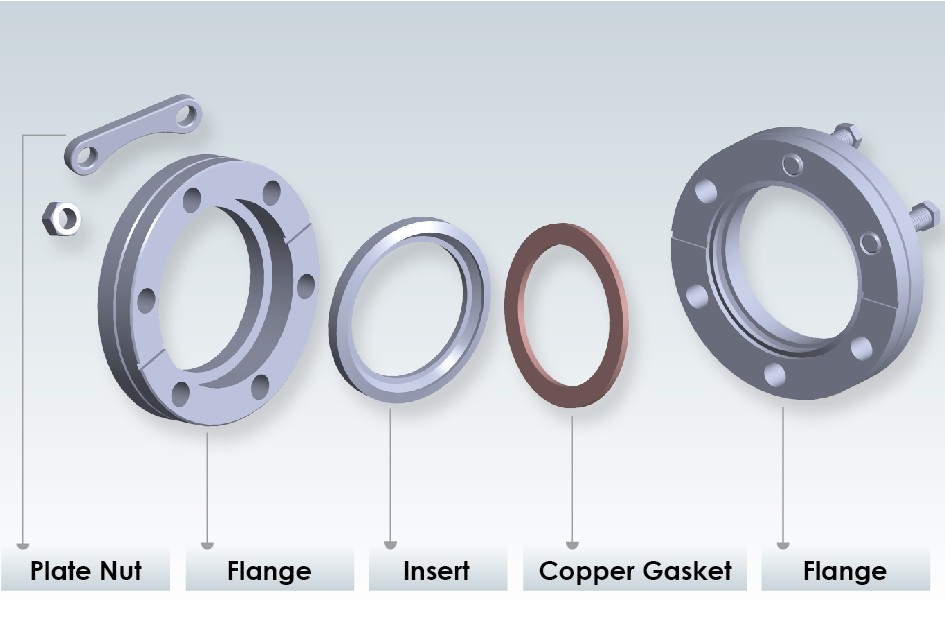

A flange bolt is different from a standard bolt. Unlike other bolts, it features a broad surface area beneath the head to render a smooth distribution of securing pressure. This wide space acts as a washer, thereby eliminating the requirement to look for an additional spare for application of such bolts.

Flange bolts are available in diverse range in our store in terms of sizes, configuration and strength. Like other rivets available in the market, these bolts are equally capable of undergoing various applications which require them.

Our specially designed flange bolts are enabled with special anti-rotational teeth features, which are designed to bite or dig into any hardened material necessary for fastening purposes. These are quite similar to the locking rings, which one might have seen on a milk jug or soda bottle.

The ‘teeth’ present on the these rivets can be turned backward, but however, requires more force. This kind of specification is what makes a flange bolt anesthetically and strategically different from a common bolt.

To facilitate more, we’ve made an essential addition to our flange bolts are the flange nuts. While these look like the ordinary nuts, one portion of the flange nut is wider than the other only to ensure equal pressure distribution. Both of these metal pieces work together, thereby reducing costs by eliminating the need for buying separate washers.

We also make sure that Always remember that proper torque on a flange bolt-nut combination ensures that the rivets never get loosen by themselves, except for the external force such as a mechanic, which can loosen these types of flange bolts.

Our specially designed fasteners are suitable with any kind of flange system. The strength ratings along-with sizes and grades can be changed depending upon the type of application. We offer sizes as per the Society of Automotive Engineering (SAE) measurements, such as 1/4 inch and 1/2 inch. Besides, we also deal with metric measurements, such as 8 mm and 10 mm.

Our vast range of products can easily fit in with anybody’s requirement, no matter whether it’s for personal or industrial use. Our ranges of products are designed with high quality and modern techniques. Keep reading to know more about this particular product!

The flange bolts are usually used in vehicle frames, especially in trucks and anywhere a head bolt is required. They feature a nozzle, thereby speeding the assembly while eliminating the washer. They render four times the bearing area than of a standard hex screw.

These types of fasteners are produced from high carbon alloy steel, which help them manage with the 150,000 PSI of minimal tensile strength. These fasteners are available in diameters ranging between 3/4″ and 3/8″ and lengths up to 31/2″, measured from the base of the head.

These particular fasteners are used with Grade G Style Lock Nuts, so as to develop a sturdy bolt system that would not only render a wider area, but also resist loosening. These rivets are also known as hex flange screws, hex frame flange bolts and hex washer frame bolts.

The 12 point flange bolts, which are also known as counter bore cap screws, are used in aircraft devices and in various automotive applications. Their major advantage is that they can be easily installed, by simply using a 12 point socket and well-ventilated impact wrench. These are also used in bikes along with wrenched decorative heads, thereby enhancing the look.

While going for a nut with flange bolt, it’s always important to check-out of the grades of the nuts and bolts are same. You should always go through the instructions if you are not much aware about the application.

Leave a Reply